On Valentine’s Day, people can expect to get heart-shaped treats and heart eyes emojis from the special people in their lives ranging from spouses and significant others to BFFs. Meanwhile, a different kind of BFF, Redwire’s 3D BioFabrication Facility, has made progress toward producing actual heart tissue. Redwire’s BFF is a 3D printer that can manufacture human tissue in microgravity. Originally developed by Techshot, which joined the Redwire family in 2021, BFF technology holds the potential to one day improve the lives of people waiting for organ transplants on Earth.

More than 100,000 people in the United States are on organ transplant waiting lists. This is in part because of there not being as many organ donors as people in need of organs. With the exception of kidneys and parts of livers, organ donation happens after an organ donor has died. In addition, not just any organ will do. Donors and recipients must have matching immune system profiles. Without a good match, the recipient’s immune system would reject the donated organ. Even with a perfect match, an organ transplant patient is still required to take immune suppressing drugs for the rest of their life to prevent rejection.

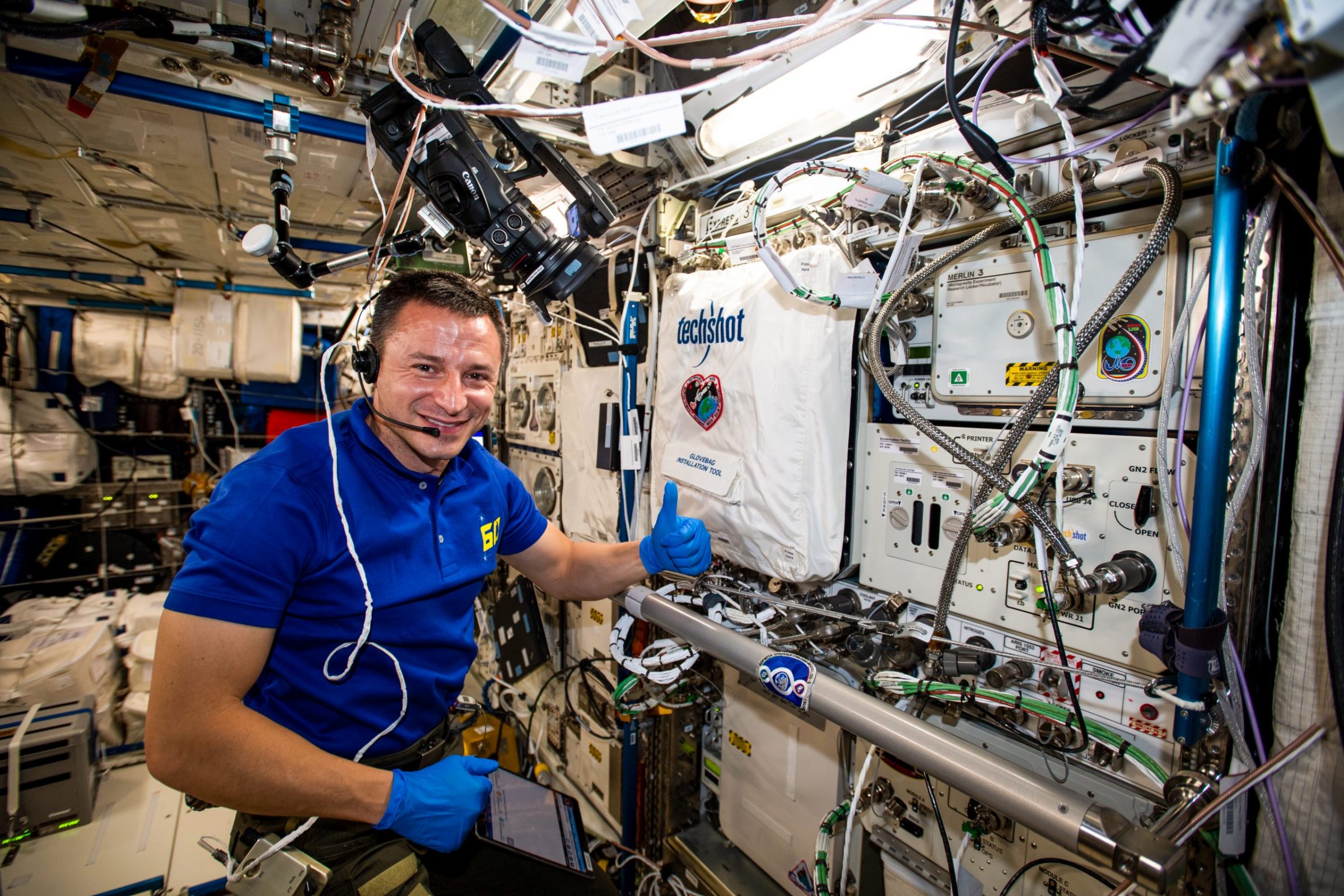

One promising way to both eliminate the need to wait for a matching donor and reduce the risk of rejection is by manufacturing replacement organs using a patient’s own cells. 3D printing is a promising candidate for enabling this capability, and Redwire’s BFF has been demonstrating this technology since its launch to the International Space Station (ISS) in the summer of 2019. BFF is currently on the ground awaiting reflight to the ISS on Northrop Grumman’s NG-18 resupply mission.

The key to BFF’s operation is stem cells, which are cells that can be turned into different cell types like cardiac muscle, nerve, or vascular cells. Depending on the type of tissue being printed, BFF can use cells that have been differentiated from stem cells, like cardiac cells, or human stem cells. Using cells collected from the person who will receive the printed tissue, known as autologous cells, means that the printed tissue can be implanted without the risk of rejection.

Researchers can differentiate stem cells into different cell types and have been able to 3D print bone and cartilage using differentiated cells; however, Earth’s gravity makes 3D printing softer tissues nearly impossible. Thick layers of softer tissue collapse under their own weight on Earth. On the other hand, the microgravity environment of the ISS allows BFF to take Earth’s gravity out of the equation.

In early 2020, BFF successfully printed human heart tissue samples that were later returned to the ground for study and analysis. Cardiac muscle, nerve and vascular cells were printed using a specially designed structure that helps support printed cells while they grow into self-supporting tissue. Through continuing tests, BFF is printing thicker and thicker samples of heart tissue. These tests could last through 2024 and are expected to lead to patches of heart tissue that would be thick enough to repair damaged heart tissue.

BFF is just one of many Redwire technologies focused on biological and plant sciences available for use onboard ISS, including: the Bone Densitometer, the Advanced Space Experiment Processor and the Multi-use Variable-gravity Platforms.

Although Redwire’s BFF may not send Valentine’s Day flowers or cards, the techniques and technologies developed and lessons learned during its operation could pave the way for production of tissues and possibly even solid organs like livers, kidneys and hearts. 3D printing tissues also has benefits beyond organ replacement. BFF printed tissue for use in research opens the door to having more robust drug discovery and disease research. Although printing an entire organ could be at least a decade away, the work being done now is an important step in advancing this critical, life-saving capability.

The work with BFF and other facilities on ISS highlights how the research being done in space is making life better for those on Earth. Redwire is continuing to support these critical initiatives through its work developing commercial payloads and managing critical science while advancing its mission to accelerate humanity’s expansion into space.