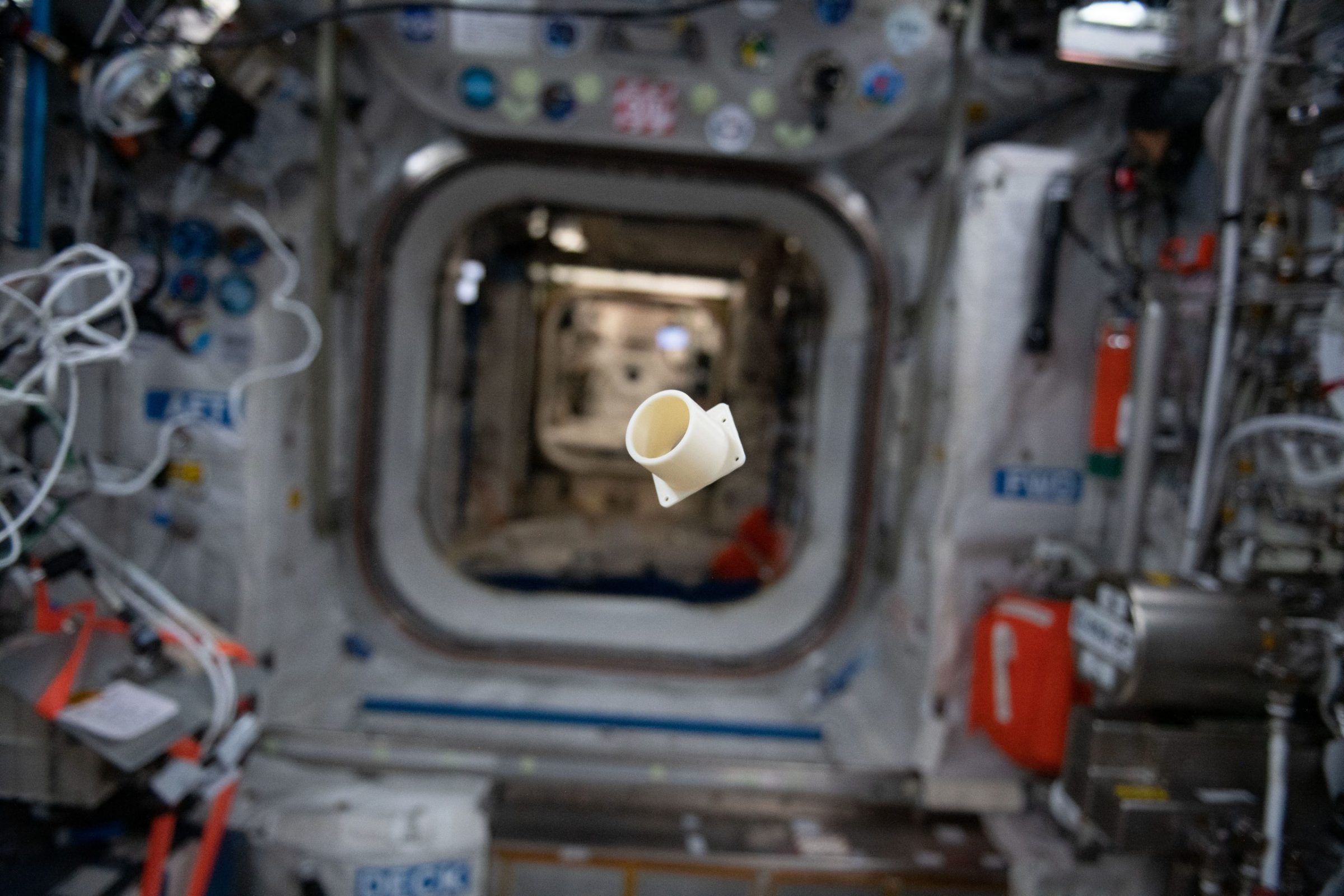

Redwire’s Additive Manufacturing Facility (AMF) recently 3D printed a part to keep the International Space Station’s (ISS) Brine Processor Assembly (BPA) working smoothly.

The 3D printed part is an adapter to the BPA exhaust outlet and allows ducting to connect to a set of filters to remediate odors from BPA. The BPA is a technology demonstration that ties into the space station’s Environmental Control and Life Support System, designed to improve water recycling on ISS and for future Artemis missions.

The use of the 3D printed adapter provided a better connection to the BPA exhaust, which allowed the BPA to continue running.

The AMF is a commercial 3D printing facility onboard ISS. Since its installation, it has been used by numerous customers and has printed over 200 tools, assets, and objects in space. The ability to manufacture on demand increases the reliability of long-duration missions and makes human spaceflight missions safer, providing additional flexibility in responding to situations that threaten a mission.