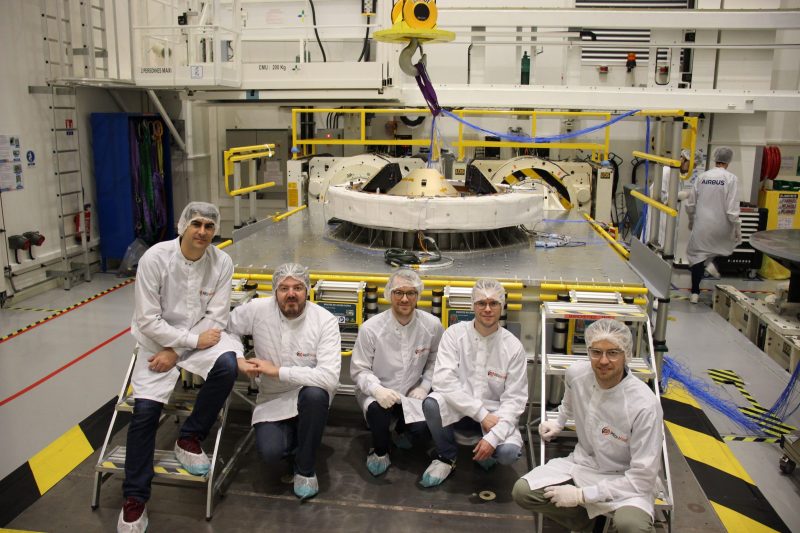

To overcome the limitations of conventional docking systems, Redwire has developed a highly versatile, resilient, high performance, and low impact berthing and docking solution that is fully computer-controlled and designed for use with both large mass and very lightweight spacecraft – and it’s recently completed successful environmental testing in Toulouse, France.

The International Berthing and Docking Mechanism (IBDM) is the culmination of an extensive research and development program undertaken by Redwire, the European Space Agency’s prime contractor for IBDM, and its partners Sener and Beyond Gravity.

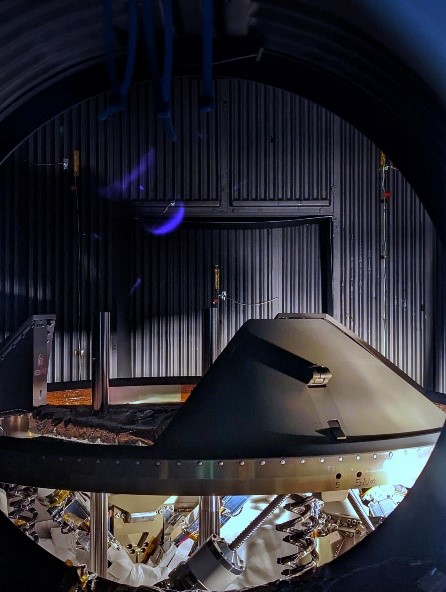

As part of the qualification process for IBDM, it must complete environmental testing. This testing includes vibration, shock, electro-magnetic (EMC) and thermal-vacuum (TVAC) testing, which are essential to prove the hardware is working properly and suitable for human spaceflight. Soon, IBDM will complete a new round of testing: EMC tests followed by a second round of environmental tests, with a goal of having a fully qualified system by the end of the year.

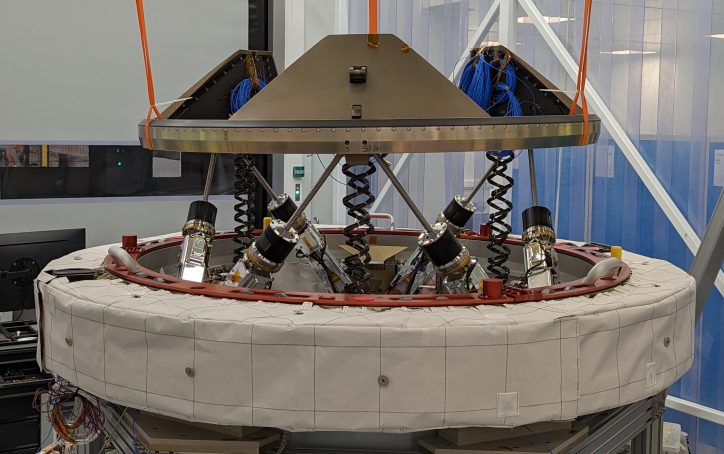

IBDM is composed of a Soft Capture System (SCS) and a Hard Capture System (HCS). The SCS is activated upon first contact and performs capture, dissipates the relative velocity of the two vehicles, and then aligns the docking pairs for hard docking. The HCS allows solidification to the interface, allows for pressurization of the docking vestibule, and connects the electrical and/or fluid umbilical’s. The HCS also grants undocking through the use of separators.

IBDM is fully redundant and compliant to the International Docking System Standard. It can be used in the following applications:

- Autonomous docking of crewed vehicles, cargo vehicles, station modules.

- Safe capture and damping in case of vehicle power failure.

- (Re-)Berthing of vehicles.

- Resource transfer through automated umbilical mating

This capability adds to Redwire’s portfolio next-generation, mission enabling technology for today’s most complex space missions and building a robust space economy.