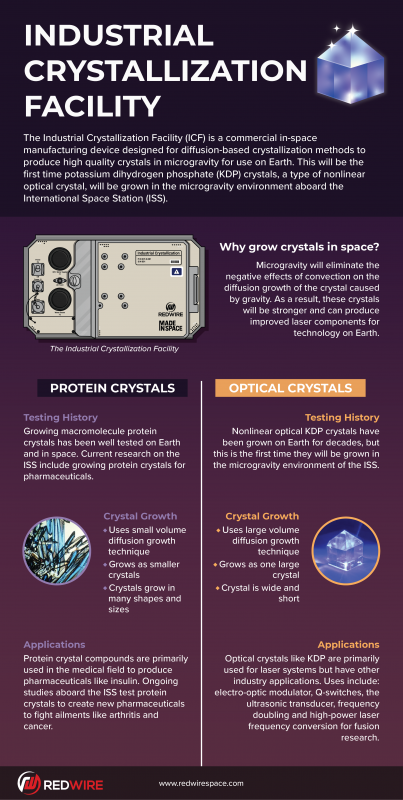

The Industrial Crystallization Facility (ICF) is a commercial in-space manufacturing device designed to provide proof-of-principle for diffusion-based crystallization methods to produce high-quality optical crystals in microgravity relevant for terrestrial use. ICF launched to the International Space Station (ISS) on Northrop Grumman’s CRS-15 on February 20, 2021.

Expanding on Redwire’s space-enabled manufacturing capabilities, the ICF mission focuses on advanced materials engineering to explore diffusion-based crystallization methods that are not viable on Earth because of thermal convection. Space-enabled manufacturing leverages microgravity to produce materials that are either completely new or enhanced compared to their counterparts on Earth. These materials could improve performance of industrial machines and systems that we use on Earth. ICF will offer important insight into microgravity-enabled growth processes for industrial crystals, which could yield opportunities for commercial production on-orbit.

Redwire has identified a solution growth technique targeting potassium dihydrogen phosphate (KDP), a type of nonlinear optical (NLO) crystal. KDP crystals have been studied since the 1930s and commonly used within industry, including well-defined laser applications. These crystals are often subject to laser-induced damage which limits the output of the system. This damage is often caused by impurities created during the crystal growth process. With ICF, diffusion-based crystallization techniques can avoid growth disturbances from thermal convection to potentially yield crystals with high optical quality that may be used to produce improved laser components on Earth. This will be the first time a KDP crystal has been grown aboard the ISS.

The KDP Growth Process in Microgravity

There are several crystal growth techniques, with each growth process optimized for various types of crystals. Redwire’s objective with ICF is to evaluate KDP crystal growth process in microgravity and establish a baseline comparison between terrestrial and on-orbit KDP crystals as well as key end-use applications.

Existing low-temperature solution growth methods take days or weeks to complete, so parabolic flights and suborbital vehicles are not suitable for establishing process baselines and making effective comparisons.

ICF eliminates the negative effects of thermal convection on diffusion growth of the crystal in microgravity. Through the solution growth technique, the gravity independent diffusion process could yield a much higher laser damage threshold with fewer inclusions and defects.

With the successful completion and understanding of the diffusion process in microgravity, this growth technique can be applied to other materials and crystals that are currently being identified by Redwire as having high-return commercial use cases on Earth.

Applications of Space-Enabled Crystals

KDP crystals are used for a variety of applications, including high-power, large laser systems. Because of their good UV transmission, high laser damage threshold and birefringence, KDP crystals are among the most widely used commercial NLO materials. KDP crystals are usually used for doubling, tripling and quadrupling of Nd:YAG laser systems at room temperature.

Other applications for KDP crystals include electro-optic modulators, Q-switches, ultrasonic transducers, frequency doubling and high-power laser frequency conversion for fusion research. The NLO crystal market, which includes several different NLO crystals, including KDP, is estimated to be worth $7.8B by 2026.

Commercialization

ICF represents another near-term opportunity to spur demand in low-Earth orbit (LEO) by leveraging a commercial capability that delivers value to industries on Earth. This technology also expands utilization of the ISS into previously uninvestigated optical products. ICF is an EXPRESS rack single locker-sized module with interchangeable components, making the facility readily available for future crystal growth experiments.

ICF is one of several Redwire facilities aboard the ISS focused on commercializing space-enabled material development, such as the recently launched Ceramics Manufacturing Module (CMM). CMM was the first demonstration of stereolithography ceramic fabrication in space. Another facility, the Made In Space Fiber Optics miniature fiber-pulling machine, focuses on producing high-quality exotic ZBLAN fiber for long-haul telecommunications purposes. Following the launch of ICF, Redwire plans to launch a superalloy casting module to the ISS.

Learn more about ICF mission: Redwire To Launch New Technology to the International Space Station Focused on Improving Laser Optics Products

Related news: International Space Station National Laboratory “Redwire to Develop a New Industrial Crystal Growth Platform on NG-15”