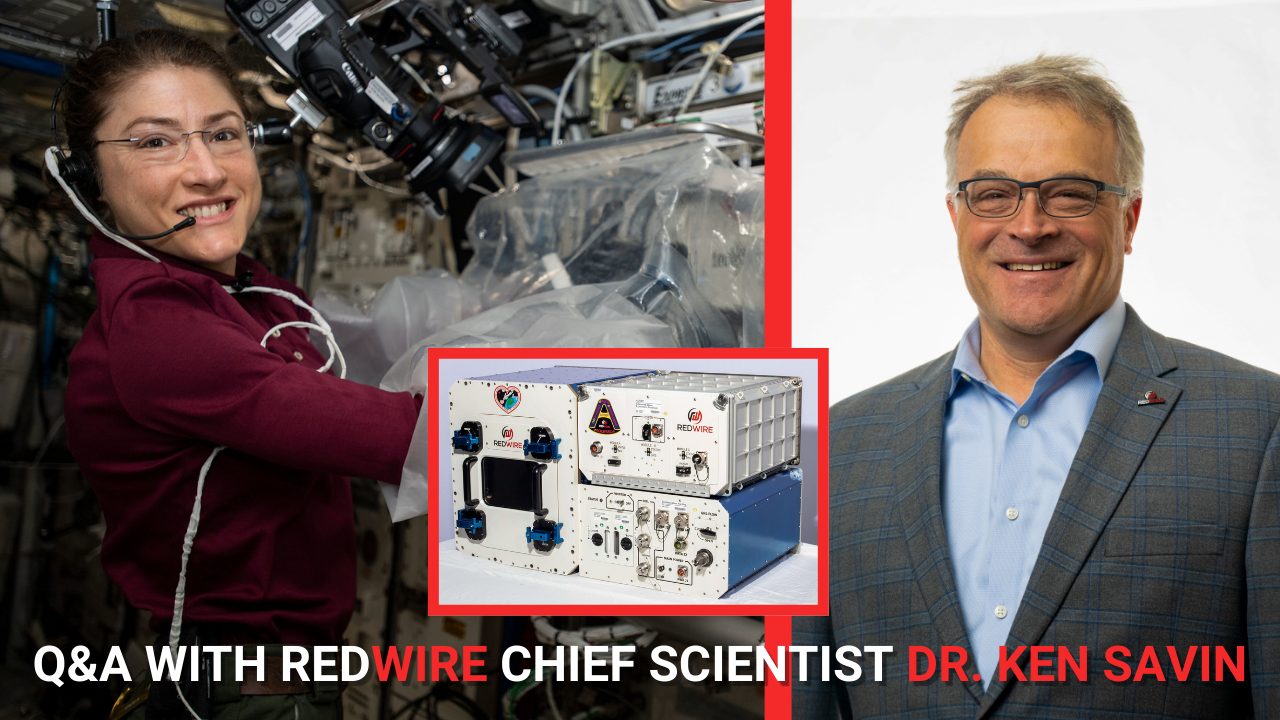

Dr. Ken Savin joined the Redwire team in early 2022 as Chief Scientist with a 20-year legacy in the pharmaceutical industry and has championed new technologies like Redwire’s 3D BioFabrication Facility (BFF), which is launching to the International Space Station (ISS) onboard Northrop Grumman’s 18th commercial resupply mission on Nov. 6 at 5:50am ET from Wallops Island, Virginia.

We asked him a few questions about his career, the technologies he’s developed, and advice for students or early career professionals.

What is your role at Redwire?

I am the Chief Scientist at Redwire. At Redwire, we design and build hardware to help people accomplish science and production goals in space. That is where I spend most of my time – helping design the products and concepts for hardware that will deliver solutions to astronauts, industry, and people on the ground.

Where did you go to school and what did you major in?

I went to Occidental College in Los Angeles and majored in chemistry. I went on to earn a Ph.D. at the University of Utah (Go Utes!) and did a post-doctoral fellowship at the Memorial Sloan Kettering Cancer Research Center in Manhattan.

What is Redwire’s 3D BioFabrication Facility?

The 3D BioFabrication Facility is a bioprinter designed to manufacture human tissue in the microgravity environment. Utilizing adult human cells (such as pluripotent or stem cells), the system can create tissue in space through technology that enables it to precisely place and build ultra-fine layers of bioink – layers that may be several times smaller than the width of a human hair – involving the smallest print tips in existence.

The BFF system being launched on NG-18 will print a meniscus, or knee cartilage, as a replacement for tissue that has been lost or damaged as part of the BFF-Meniscus-2 investigation, a collaboration between Redwire and the Uniformed Services University of the Health Sciences Center for Biotechnology (4DBio3). Although it’s not “organ replacement,” this kind of tissue therapy will be a lead into true organ replacement therapy and represents a significant step forward for the research performed in space and as a benefit to humanity on the ground.

Why is biotechnology research in microgravity important?

Efforts to produce organs will require a lot of preliminary work. When we perform this bioprinting on the ground, unless we add fixatives or matrix materials, the printed mixes tend to be very “runny” and spread out like other fluids does terrestrially. In the microgravity environment of low-Earth orbit, the printed materials tend to hold their form and stay in a three-dimensional shape.

Microgravity gives us new opportunities to learn, develop our science, and understand the processes and techniques that will make organ production possible. Systems like BFF can be used to test pharmaceuticals and mimic more complex systems for study and experimentation.

What gets you excited about this type of research?

Work for me has changed over the years. I used to go to a lab in a big building and do chemistry. I have been an administrator and a team lead for science and operations efforts. It was always fun, but it was work. Now I get to think about what we will do in space, the final frontier! Things that will make the lives of people on Earth better and potentially move humanity into deep space.

The best part is that I get to work with a team of extremely talented engineers, scientists, partnership developers and teams who build programs and hardware around the ideas we come up with and execute the work in orbit. It is like being part of a great science fiction series that goes on week after week that we can direct and in the end is really happening!

Do you have any advice for students or aspiring aerospace professionals?

I see science and the development of industrial applications in low-Earth orbit and beyond growing in significance in the coming years and decades. The keys to this industry are to be open-minded and know the basics. Here are some things I would recommend:

- Doing well in school and studying the fundamentals like chemistry, biology, math and physics are important. These foundational areas will allow you to see opportunities that others will not recognize, and it will allow you to contribute to next-generation technical efforts.

- Knowing how products are made and how they bring value to society are critical to understanding how working in space can benefit people on the ground. The real value of work in space will be a result of exploration and in-space production of technologies that cannot be made on Earth. My time in the industry helped me see how products are made, how value is created and to see how design and marketing drive innovation and investment. But the most important thing I walked away with was the significance of being able to tell a good story about what you do and getting others to see your ideas for what they are and supporting you.

Dr. Ken Savin’s Bio

After receiving his Ph.D. from the University of Utah in synthetic organic chemistry, Dr. Savin went on to do a post doc at the Memorial Sloan Kettering Cancer Center before going on to work for Eli Lilly and Co. as a senior research Scientist. During his 20-year career in the pharmaceutical industry, Ken led discovery chemistry research teams, discovery operations, radiochemistry, drug disposition, chemistry development and product teams. During the last four years of his industrial career, he led an effort that resulted in five separate flight experiments flown on the International Space Station. After retiring from Lilly, he joined the team at The Center for the Advancement of Science In Space (the operators of the International Space Station US National Lab) working in both Business Development, as a science lead and ultimately as the Sr. Director of In Space Production Applications. Ken joined the Redwire team in early 2022 to be the Chief Scientific Officer of Redwire.

Learn more about the Redwire technology launching on NG-18 here.