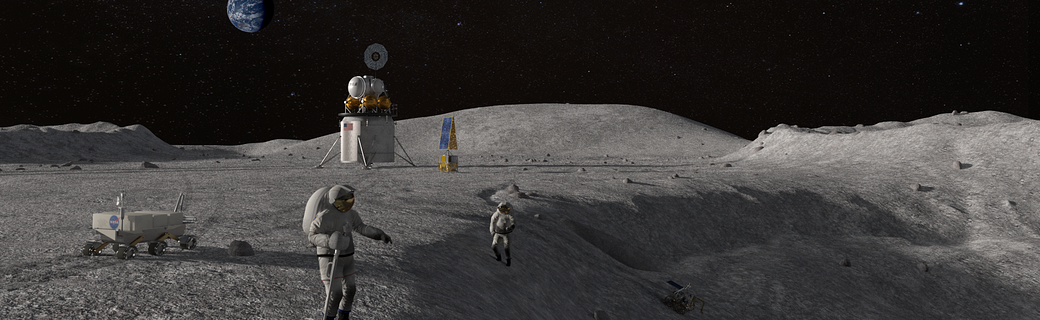

NASA’s Artemis program signals the next era of human spaceflight and exploration as the agency prepares to send the first woman and the next man to the lunar surface by 2024. This milestone will pave the way for sustainable lunar operations for NASA and its partners by the end of the decade.

To meet these goals, NASA and commercial partners are looking to rapidly develop critical technologies to enable human and robotic exploration on the Moon and eventually Mars. A key priority within NASA’s space technology development portfolio is maturing in-situ resource utilization (ISRU) capabilities—specifically technologies to carry out surface excavation, manufacturing and construction duties.

Lunar manufacturing and construction technologies are important for near- and long-term exploration missions to the Moon to develop critical infrastructure, support science objectives, and eventually support long-term infrastructure for sustainable cislunar economic activity. Building infrastructure such as stable foundations, lunar habitats, hangars, barriers, support structures and even launch pads will be essential elements to support lunar operations during every phase of the Artemis program.

While NASA is poised to make long-term investments to advance ISRU technologies, commercial innovation in these areas will be important to augment NASA’s technology roadmap. Made In Space, Inc. (MIS) has expanded its portfolio of space manufacturing solutions as the company looks to develop a new integrated system of ISRU capabilities that will enable regolith-based in-space manufacturing and construction along with additional multi-material manufacturing processes optimized for extreme environments.

Championing ISRU Technology through Public-Private Partnerships

NASA’s Space Technology Mission Directorate (STMD) and its Lunar Surface Innovation Initiative (LSII) aim to accelerate the technology readiness of key systems and components needed for lunar surface exploration. With ISRU being a priority, NASA is looking to industry to provide innovative solutions for multi-use, multi-material manufacturing technology that will augment the agency’s existing investments in lunar technology development.

NASA’s Centennial Challenges and its Additive Construction for Mobile Emplacement project have provided valuable insights into lunar manufacturing techniques, but there is an opportunity for rapid commercial technology development to extend these efforts and deliver valuable near-term pathfinder technologies that can push the envelope on current processes and products to support the needs of many NASA missions.

Additionally, NASA’s Commercial Lunar Payload Services (CLPS) program, which further demonstrates the agency’s commitment to public-private partnerships, will provide an early opportunity to validate and demonstrate innovative ISRU technologies developed through industry partnerships.

NASA’s space manufacturing heritage is tied to its longstanding partnership with MIS. Dating back to 2014, NASA and MIS have demonstrated the utility of on-demand 3D printing on the International Space Station (ISS) and that technological innovation has now fostered new advancements in on-orbit servicing, manufacturing and assembly through the Archinaut One program. As NASA prepares to return to the moon, this collaborative space manufacturing heritage could yield even greater value for ISRU manufacturing.

Novel Technologies for Advancing ISRU Capabilities on the Lunar Surface

Launching raw material to the surface of the Moon is cost prohibitive and, in many instances, unnecessary. There are plenty of resources on the lunar surface that can be used for construction activities. Advances in additive manufacturing make it possible to use the regolith harvested on the Moon to construct habitation elements on the Moon. Accelerating technology development to augment the Artemis roadmap will necessitate mature lunar manufacturing capabilities within the cadre of ISRU capabilities.

In recent years, MIS has developed a range of pathfinder technologies to address ISRU priorities including new capabilities for metal manufacturing, recycling, self-repairability, and electronics printing.

To optimize the utility of these advanced technologies for lunar exploration, MIS aims to develop an integrated suite of manufacturing and construction technologies that would provide a flexible and affordable solution for use in relevant environments including early lunar payloads, Lunar Gateway, or in future free flyers.

This new, integrated system of capabilities will demonstrate techniques and collect data for enabling the production of tools, surface structures, habitation infrastructure, landing pads, reinforced foundations, radiation protection, and equipment for communications, mining, and power generation and transmission.

An integrated lunar manufacturing system, developed by MIS, would address key ISRU priorities through a range of distinct capabilities including:

- Delivering welding technology to enable joining, repairing, and cutting operations in situ through a single, efficient tool. Lunar welding supports activities such as connecting piping for waste disposal and storage, fabricating elements to create housing, shielding, or communications arrays.

- Enabling bulk manufacturing and scalable production of regolith bricks for flat surface and pressurized interiors for habitation storages or liquid storage units. This technology can also be manufactured into reflective surfaces for antennas and thermal mining mirrors.

- Enabling precision manufacturing of architectural brackets, fasteners, and connectors.

This integrated system, built on legacy MIS technology, could inform new construction and manufacturing techniques that only require access to surface regolith, rather than deep mining or resource extraction.

Long-Term Impacts: A Sustainable Lunar Presence and Further Exploration

While ISRU has been recognized as an integral part of the Artemis plan, it is also one of the most cited technology gaps when considering long-term space exploration and settlement. Developing lunar manufacturing capabilities, through the Artemis program, will be critical to overcome ISRU technology gaps, accomplish NASA’s science and exploration objectives on the lunar surface, and enable sustainable human and robotic operations beyond Earth.

A 2020 AIAA proceedings report stated:

“The goal of achieving economic viability on the moon is only possible if the capability exists to detect, extract, process, and utilize lunar resources. Large-scale resource mining for lunar regolith, water, and volatiles must be developed that can operate autonomously (or semi-autonomously) and in the harsh lunar environment. Autonomous processing and additive manufacturing capabilities will allow these resources to be utilized to build infrastructure and hardware components, life support, and agricultural systems, as well as fuel for surface and launch/landing transport systems. With such an unproven technology, it is vital that ISRU be a core component of NASA’s critical path to lunar settlement” (AIAA Proceedings Report – AscendxCo-Lab on Economically Viable Lunar Settlement held on July 29, 2020)

Advancing ISRU capabilities through public-private partnerships will provide the technological foundation needed to establish a permanent presence on the Moon and pave the way for Mars exploration while also supporting cislunar infrastructure for commercial missions. NASA and its industry partners are positioned to quickly develop and mature these innovative technologies in the early phases of the Artemis program which could yield exponential value for many decades to come.