Made In Space (MIS) is helping in the fight against COVID-19 by providing front line healthcare workers with much-needed supplies and equipment. MIS facilities in Jacksonville, FL and Moffett Field, CA are providing hundreds of 3D printed face shields to local-area hospitals to augment the shortage of critical PPE supplies. Additionally, MIS engineers have developed a rapid response ventilator adapter to enable a single ventilator to safely support multiple patients in extreme situations.

As the COVID-19 pandemic evolves, healthcare professionals are facing life-and-death decisions to provide care for increasing numbers of critically ill patients using a limited supply of medical ventilators.

Splitting ventilators remains an experimental emergency treatment that has been used in crisis situations to save lives. Patients who are experiencing differing stages of respiratory distress need individualized support (volume, pressure, etc.) provided by the ventilator. The inability to adjust a single ventilator’s settings to match varied patient needs is the main challenge when supporting multiple patients on a single ventilator. Sharing ventilators also presents increased infection control issues.

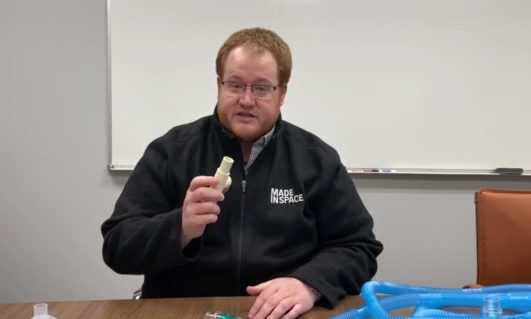

To multiply the lifesaving power of available ventilators, MIS engineers worked with local-area doctors in Jacksonville, Florida to quickly develop and test a ventilator flow adapter that can be used to safely and effectively allow multiple patients to share a single ventilator while maintaining the distinct settings required by each patient. These adapters can be quickly assembled using off-the-shelf parts available at hardware stores across the nation for less than $20. There is no special equipment needed for assembly and 3D printing is not required.

This inexpensive yet effective solution expands the capacity of a single ventilator and offers front line workers life-saving advantages including:

- Regulating airflow among multiple patients sharing a single ventilator

- Enabling continuous ventilator operation as additional patients are added or taken off the shared medical device

- Autoclavable components for sterilization

The step-by-step instructions for assembling the ventilator adapters are being shared with local-area hospitals and the information will be made available to all healthcare personnel with approval from their facility administration. To request the step-by-step assembly guide, healthcare personnel should email info@madeinspace.us.

For more details on Made In Space’s continuing efforts to support the cause check out the company blog at madeinspace.us/blog.