What We Do

Redwire is accelerating humanity’s expansion into space by delivering reliable, economical and sustainable infrastructure for future generations.

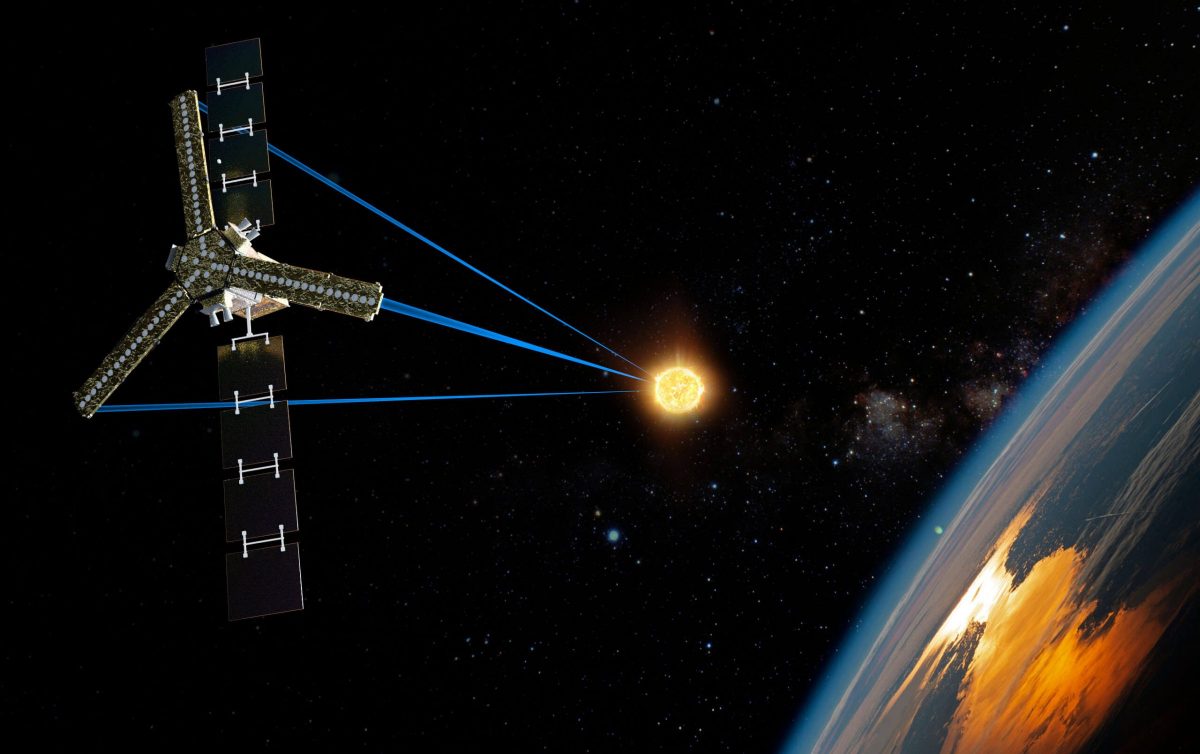

Integrated Mission Enabler

Redwire is a key mission enabler with products relevant to almost every space mission, including: power generation, antennas, deployable solutions, star trackers, and camera systems.

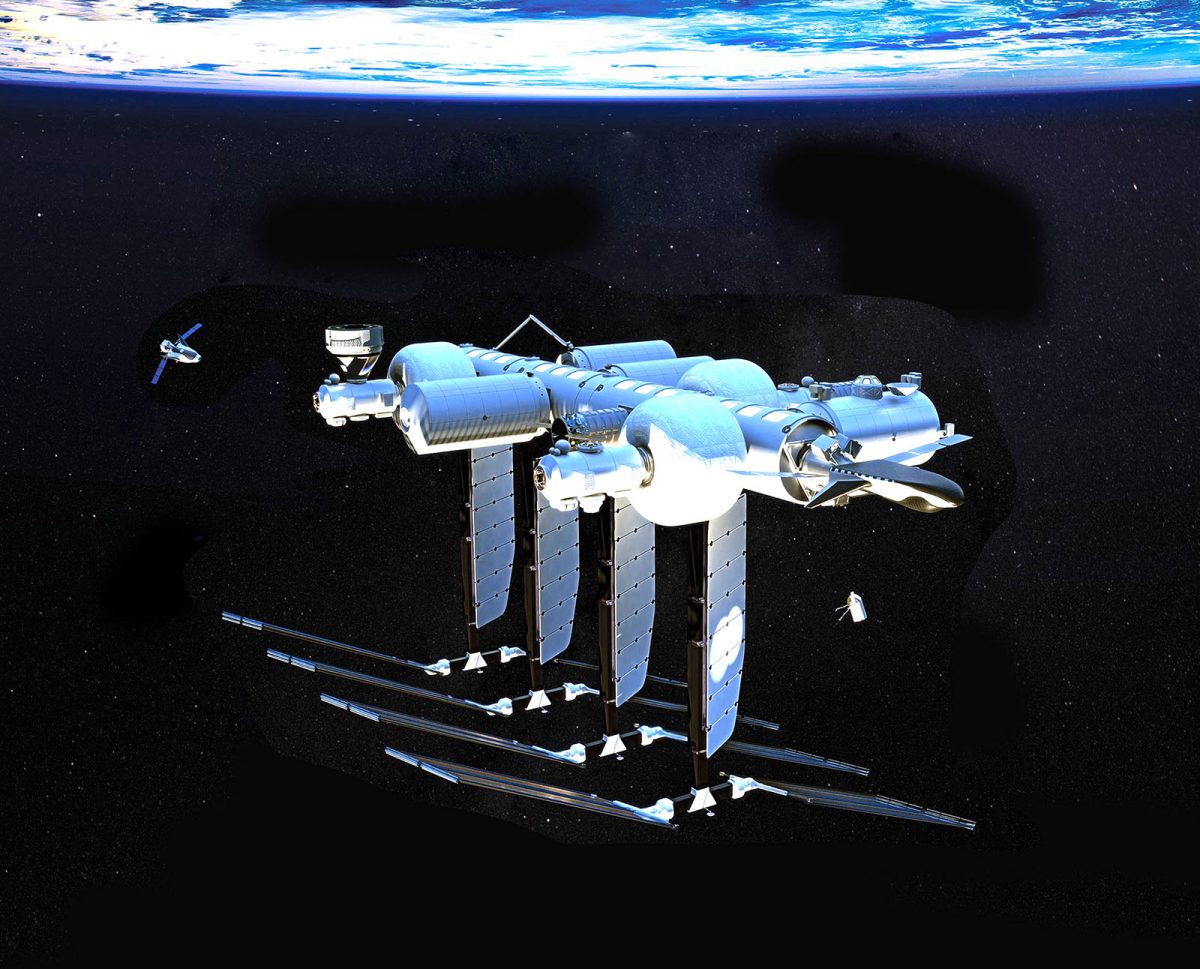

Explore, Live, and Work in Space for the Benefit of Humanity

Redwire is developing capabilities that are critical for people to live and work in space which includes microgravity payloads, platforms, and in-space manufacturing and biotech facilities.

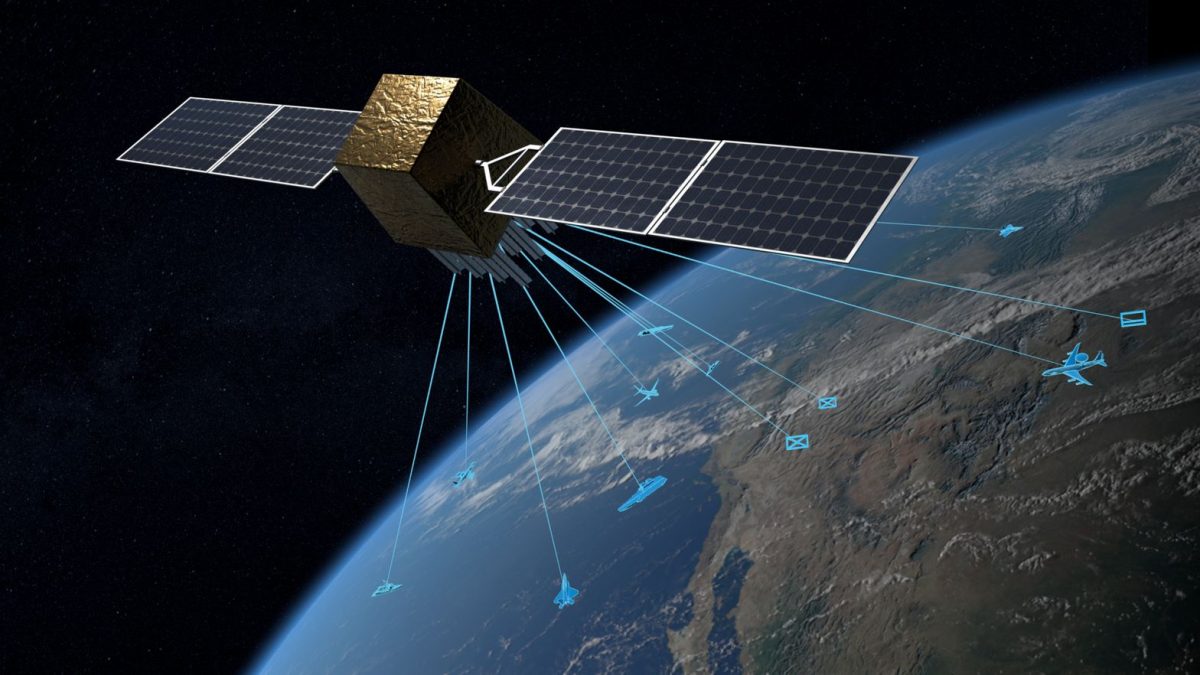

Multinational Mission Support

Redwire is supporting ambitious, multinational space exploration through products that are critical to international mission operations.

Small Satellites

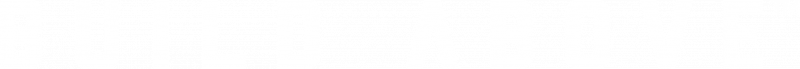

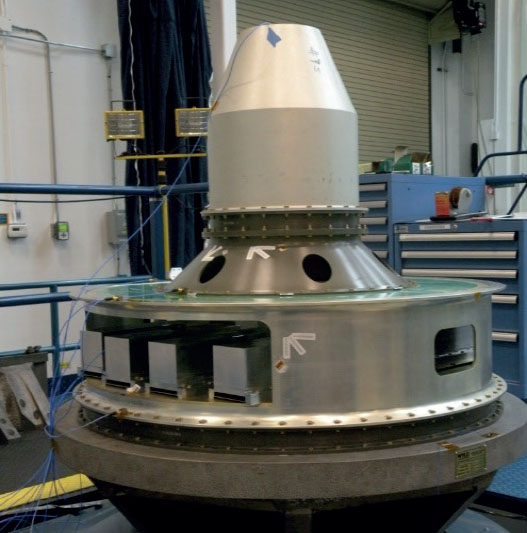

Payload Adapters

Berthing and Docking

Let's Discuss Your Mission.

Get in touch with a space solution specialist today to discuss how you can leverage Redwire technology and capabilities to ensure mission success.