A sustainable human presence on the Moon will be a reality by the end of this decade, with NASA anticipating crewed landings on the lunar surface starting in 2026. The Artemis I mission has set the stage for future missions to the Moon, which will re-establish a human presence on the lunar surface. This new long-term presence will require infrastructure to support landing and launches, exploration of the lunar surface, and sustainable, long-term operations. In-situ resource utilization (ISRU) will be crucial for building the infrastructure needed to support these activities.

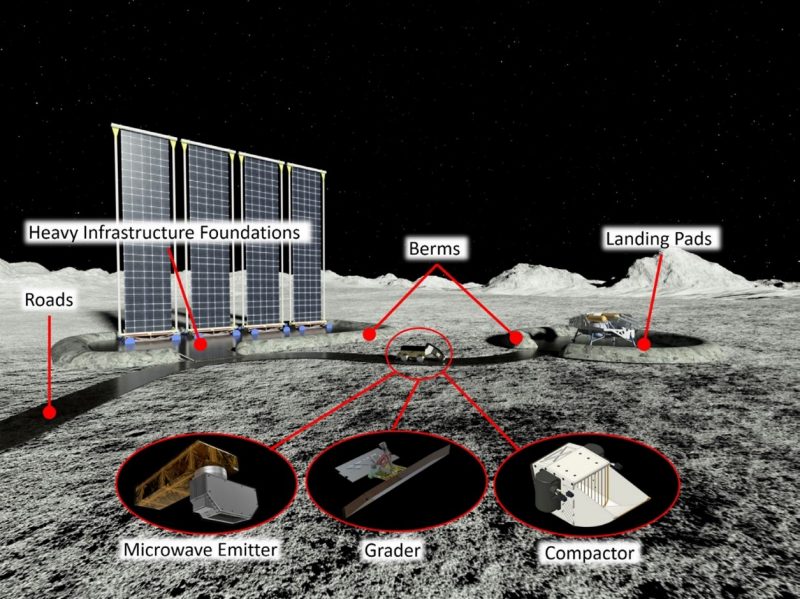

In 2023, Redwire was selected for a $12.9 million NASA Tipping Point award to prototype Mason, a first-of-its-kind manufacturing technology which seeks to build critical infrastructure on the surface of the Moon, including shielding structures (e.g., berms), landing pads, roads, and foundations for habitats. This technology could enable robust construction on the lunar surface to advance human and robotic operations, paving the way for long-term human presence and a dynamic lunar economy.

Mason technology could reduce operational risks and protect assets as lunar surface activity increases in the coming years while NASA’s Artemis campaign builds momentum. More specifically, infrastructure created by Mason technology can protect assets from the dangerous regolith ejecta that will result from regular launch and landing activity, improve mobility, and reduce the impact of abrasive dust on critical components. Mason is a tool suite scalable to any lunar rover, vehicle, or robotic arm. Next-generation Mason technology will open the door to a robust lunar economy and advance a much-needed capability for the lunar construction.

The Mason team, led by Redwire, includes Lambda Technologies, NASA Kennedy Space Center’s Swamp Works, Colorado School of Mines, and the University of Central Florida.

How Does Mason Technology Work?

Mason is a tool suite comprised of a grader, a compactor and a microwave emitter, as well as instrumentation for process control and quality verification. Once mounted to a mobility platform (e.g., a rover), Mason’s Grader tool is utilized to push away rocks and level out surfaces. After grading, the Compactor is used to densify the regolith. Finally, the Microwave Emitter is used to sinter the regolith; that is, it uses microwave energy to heat the regolith to extremely high temperatures, such that the once powdery regolith fuses together to form a solid with properties similar to concrete.

Mason revolutionizes construction on the lunar surface by eliminating many of the complex pre-processing steps required for alternative construction methods, including mining, milling, screening, magnetic separation, calcining, curing agent extraction/purification, binder synthesis/purification, metering and mixing. Furthermore, the in situ microwave sintering method of construction implemented by Mason avoids the high cost of launching any construction material additives to the Moon, relying entirely on locally available regolith material. The in situ microwave heating technique implemented by Mason is considered by lunar experts to be the most cost-effective method for building landing pads.

Mason’s approach of grading, compacting, and microwave heating requires relatively simple tools and is based on commonplace terrestrial processing techniques. This simplicity lowers the risk of using Mason for critical lunar infrastructure. The Mason tool suite is also extremely versatile, scalable and platform agnostic, making it an ideal construction solution.

Implications for Future Lunar Infrastructure

Dust mitigation is of primary importance to enable a long-term presence on the moon. Before sintering, lunar regolith is a fine, abrasive powder. This powder is extremely harsh on optical equipment and mechanisms, leading to rapid equipment failures. High-velocity regolith ejecta produced through rocket engine Plume-Surface Interactions (PSI) around launch and landing sites can be devastating to nearby structures and apparatus. Furthermore, mobility through regolith is exceedingly difficult, with rocks, craters, and fine sand posing significant threats; this is a significant challenge faced by rover developers. These problems are eliminated after leveling, compacting, and sintering regolith with the tools developed under Redwire’s Mason program.

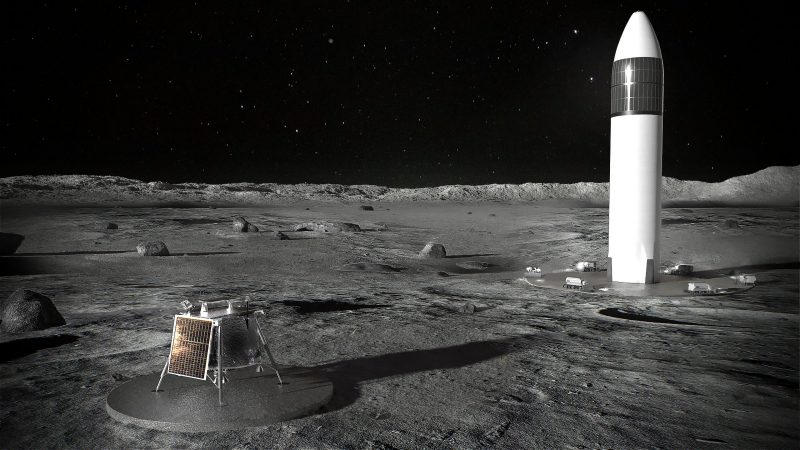

As the Artemis campaign advances, there will be an increase in activities on the Moon’s surface including more frequent launches and landingsas astronauts and resources arrive and depart. This presents an ongoing and escalating threat to equipment, vehicles, and infrastructure within range of this ejecta. Mason’s landing pads, roads, and berms made from solidified regolith are a vital part of mitigating this danger and facilitating a safe and productive lunar economy. Reducing the effects of PSI via Mason’s reusable surfaces also decreases the likelihood of issues between rival nations by decreasing the possibility that PSI-related damage due to launch and landing operations causes harmful interference in violation of the Outer Space Treaty.

In addition to PSI-related ejecta, lunar dust disturbed by astronauts or rovers, or attracted to surfaces through electrostatic interactions poses an insidious threat to humans, industrial and scientific equipment, and rovers during science and exploration activities. Mason’s roads and dust mitigation areas reduce the amount of loose dust. This serves to improve trafficability, reduce wear and tear on vehicles, and decrease damage to expensive assets such as solar panels, sensors, and spacesuits.

The novel capability provided by Mason could enable sustainable infrastructure on the lunar surface and incentivizes economic development by lowering cargo prices, reducing expenditures on replacement parts, and opening new locations for resource extraction. Building and maintaining a long-term presence on the Moon presents many challenges, among which is the need to protect operations and assets from damage as a byproduct of increased activity on the lunar surface.

Mason also offers other far-reaching benefits for routine lunar operations. Mason landing pads and roads shift mass from vehicle shocks and springs to cargo and science, boosting revenue for lander and rover operators. By supporting the development of roads, Mason opens up more of the Moon’s surface for science and commercial activities.

Enabling safer, lower cost lunar science and operations is vital to help NASA prepare for historic Martian missions. Mason is currently optimized for lunar regolith but could be transformed to bring the same low-cost, low-impact benefits to Mars.

Opening the Door for Sustainable Operations on the Moon and Beyond

As humanity enters into a new, exciting era of space exploration, the ability to build infrastructure through ISRU on the lunar surface will be critical for humanity’s expansion into space. NASA’s exploration and technology goals achieved through the Artemis campaign will enable humanity’s long-term presence on the Moon.

Related News: Learn more about how Redwire provided the “Eyes of Orion” for Artemis I here.