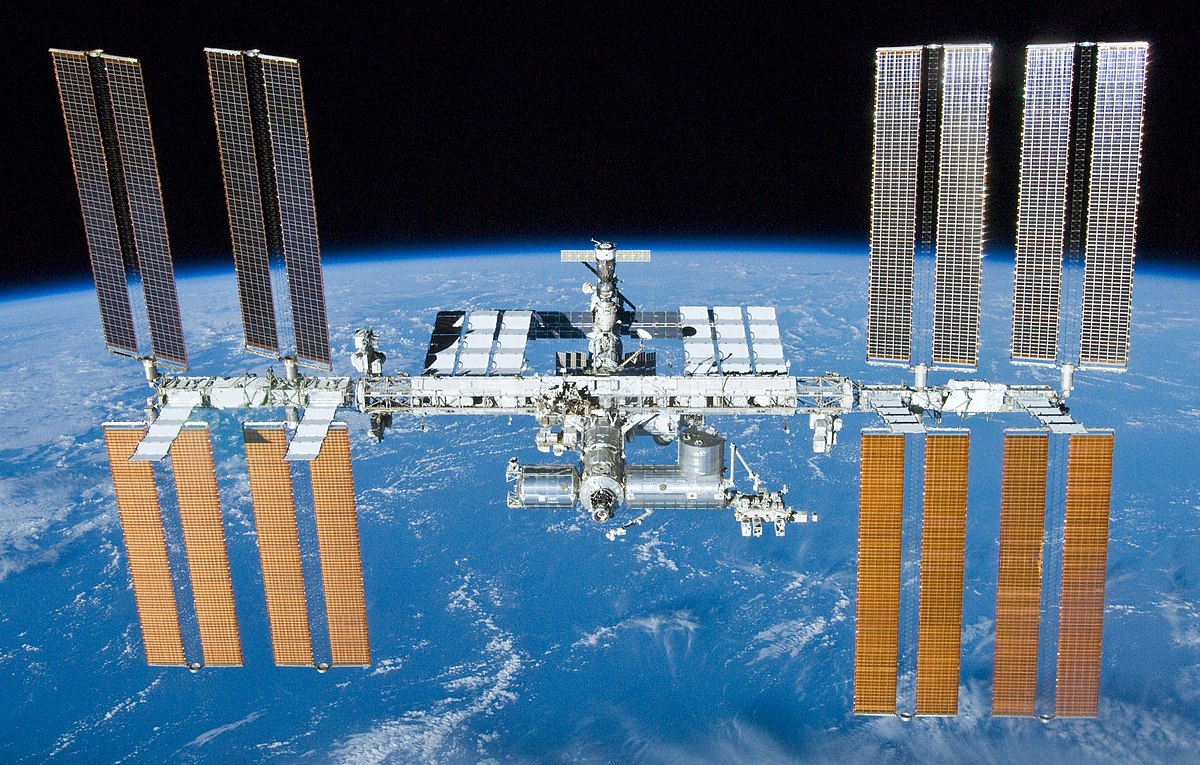

Today, Redwire subsidiary Made In Space (MIS) was awarded the Exceptional Technology Achievement Medal at the 2020 NASA Honor Awards Ceremony hosted virtually by NASA’s Johnson Space Center. The medal was awarded for the Made In Space team’s exceptional and pioneering success developing and operating in-space manufacturing facilities on the International Space Station (ISS) while furthering the commercialization of low-Earth orbit.

This prestigious NASA medal is awarded to Government or non-Government individuals for exceptional technology contributions significantly contributing toward the achievement of the NASA mission. The medal was presented to Redwire COO Andrew Rush in recognition of the team’s exceptional efforts.

To date, Redwire’s flight heritage on the ISS includes five facilities, developed by MIS teams, that have pioneered in-space manufacturing and paved the way for manufacturing with specialized materials in orbit to benefit Earth.

MIS teams are currently developing three ISS pilot payloads, through a partnership with the ISS Research Integration Office at NASA’s Johnson Space Center, that aim to catalyze and scale demand for commercial capabilities in low Earth orbit by producing high-value products for terrestrial use. The facilities include the Ceramic Manufacturing Module (CMM), Industrial Crystallization Facility (ICF), and the Turbine Superalloy Casting Module (TSCM).

CMM, which launched in October 2020 on Northrop Grumman’s CRS-14 mission successfully demonstrated ceramic additive manufacturing in space for the first time in history, earlier this week. The facility is designed to provide proof-of-potential for single-piece ceramic turbine blisk (blade + disk) manufacturing in microgravity for terrestrial use.

The next manufacturing facility set to launch to the ISS is ICF—a commercial in-space manufacturing device designed to provide proof-of-principle for diffusion-based crystallization methods to produce high quality crystals in microgravity relevant for terrestrial use. ICF will be followed by TSCM, which will investigate potential improvements in superalloy microstructure by heat treating in microgravity.

These advancements in space enabled manufacturing capabilities could signal new opportunities for low Earth orbit commercialization.