- Made In Space presented at CES 2019 alongside the ISS National Lab and Hewlett Packard Enterprise.

- Space enabled manufacturing aims to leverage the microgravity environment to produce advanced materials for global markets that are only possible via manufacturing in space.

- The International Space Station is enabling commercial space companies to experiment and scale their business models thereby benefiting the emerging market in low Earth orbit.

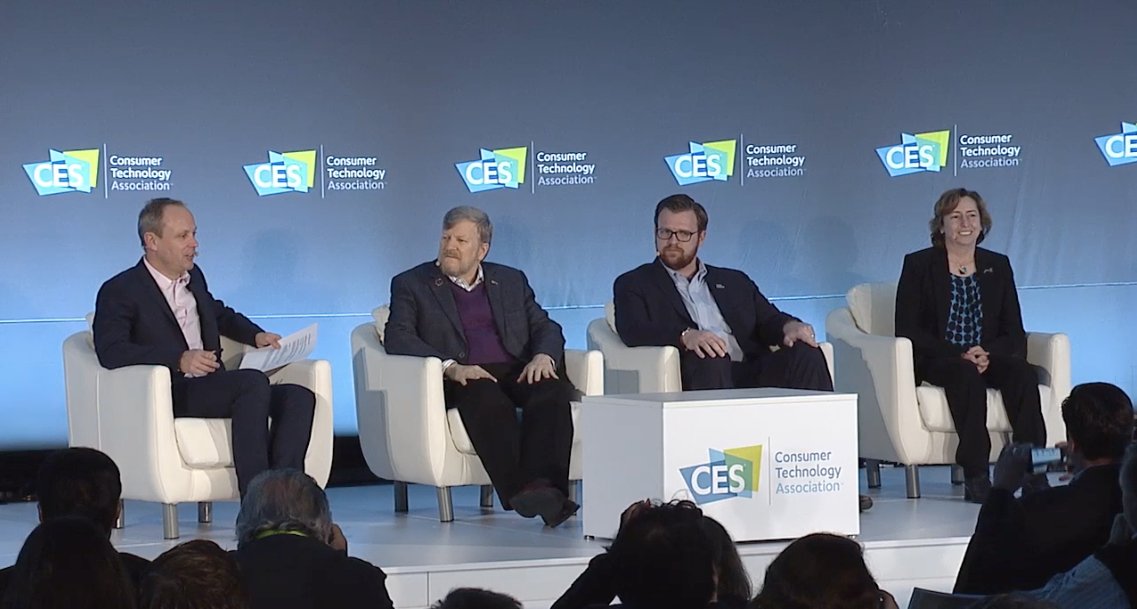

Last month, the 2019 Consumer Electronics Show (CES) took place in Las Vegas and captured the fascination of a global audience as major brands and innovators showcased the latest advancements in technologies. Amidst the glitzy wearables, LED screens, and next-gen robotics, the International Space Station (ISS) took center stage during the Exploring Tech and Advanced Materials Innovation in Space SuperSession.

The session highlighted how innovative companies are leveraging the space station to enhance their tech and products. The panel featured Andrew Rush, CEO, Made In Space; Dr. Mark Fernandez, Americas HPC Technology Officer, Hewlett Packard Enterprise; and Dr. Liz Warren, Associate Program Scientist, International Space Station U.S. National Laboratory.

Andrew Rush, CEO, @MadeInSpace details the company’s current research on the ISS National Lab that is focused on manufacturing ZBLAN optical fibers in space–this #tech could have very high value back on #Earth. #CES2019 Watch: https://t.co/jQhLDMMWTv pic.twitter.com/GGnlrWrJl2

ISS National Lab (@ISS_CASIS) January 8, 2019

This CES 2019 session elevated the conversation around advanced manufacturing and technology development in space to a global mainstream audience and also highlighted the innovative work Made In Space is leading.

“The space environment is really fascinating in terms of manufacturing, making new materials, processing new materials, and making things that have incredible economic value to folks back here on Earth”

Andrew Rush, CEO, Made In Space

During the session, Rush outlined the value and potential of space enabled manufacturing — a major focus area for Made In Space. Space enabled manufacturing technologies leverage microgravity to produce materials that can only be created in space, such as ZBLAN optical fiber. The ability to manufacture advanced materials in space that have superior capabilities when compared to materials produced on Earth creates tremendous economic opportunities.

For example, Made In Space’s Optical Fiber Production in Microgravity (OFPIM) payload, developed in partnership with Thorlabs, aims to produce high quality ZBLAN fibers in-orbit that far exceed the performance of silica optical fibers which are commonly used on Earth for telecommunications and other applications. The potential impact of ZBLAN manufacturing in space could be transformative and the pioneering technologies being developed at Made In Space are positioning the company as a trailblazer in this market. To accelerate the progress of ZBLAN manufacturing in space and strengthen its space enabled manufacturing initiatives, Made In Space is working with subject matter experts and identifying business opportunities. Through these partnerships, the company is validating business models that will accelerate marketplace adoption and increase return on investment.

Pilot manufacturing payloads like OFPIM have expanded Made In Space’s portfolio of services and anchored its ZBLAN manufacturing program, ultimately enhancing the company’s value proposition to prospective users beyond its legacy of additive manufacturing in space and there is no indication that this progress is slowing down.

Rush noted: “[ZBLAN optical fiber] is just the first of many different classes of materials which Made In Space, NASA and others have been doing research on and are now exploring and proving out the business models of manufacturing in low Earth orbit.”

The advancement of space enabled manufacturing technologies like ZBLAN manufacturing and others demonstrates the value of the ISS as a testbed for tech development. The continuous process of testing and refining these emerging space technologies is accelerated through the availability of the ISS National Lab and support from NASA.

Additionally, the ISS is a key enabler of the expansion of the low Earth orbit economy. This orbital outpost allows Made In Space and other commercial space companies an opportunity to iteratively refine and scale business models for sustainably producing high quality products in-orbit and delivering products to Earth-based customers. Companies are able to develop pilot payloads with commercial applications, validate processes, and build larger operations that can generate demand and eventually support commercial space stations in low Earth orbit. The foundation of this burgeoning space economy will rely on mature business models that have leveraged the infrastructure of the space station and ISS National Lab to transition beyond the era of government-operated platforms.

CES 2019 was a valuable opportunity to underscore the importance of a collaborative effort in building a sustainable economy in low Earth orbit. Made In Space is proud to be developing cutting-edge space tech that aims to break many barriers related to on-orbit manufacturing and the vision of the company remains steadfast on building the future in space.